Engineering responsibility for the environment is necessarily closely related to the laws governing environmental matters, but environmental degradation was not the subject of serious federal regulation until the late 1960’s. Until that time, private litigation and the common law were the principal tools for controlling pollution. Usually, however, no single individual was sufficiently harmed by pollution to be motivated to bring suit against a polluter.

Both the states and the Federal government were ineffective in controlling pollution. As a response to this state of affairs, Congress passed the National Environmental Policy Act (NEPA) in 1969. The Act inaugurated “a national policy which will encourage productive and enjoyable harmony between man and his environment….” One of the best-known provisions of the NEPA is the requirement for an environmental impact statement, which enumerates the effect of a project on the environment. Congress then created the Environmental Protection Agency (EPA) to enforce its mandates.

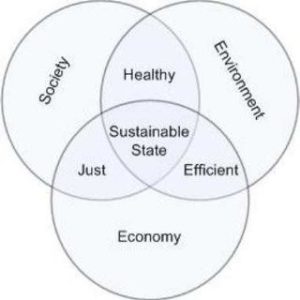

Engineering Responsibilities to the Non-Human Environment Contemporary technologically advanced civilization has made massive changes in the environment. Western society has tended to conceive of nature as passive, as the fit object of human manipulation and control. This view of nature as passive is amply reflected in our language about the natural world. Land is to be “developed.” “Raw” land is to be “improved.” Natural resources are to be “exploited” and “consumed.” Trees are to be “harvested.” The rivers are to be “harnessed” to produce electrical power.

The wilderness must be “managed.” Nature, like the rest of the non-human world, is to be subservient to human purposes. The environmental movement, so influential during the last twenty-five years, is a reaction against this attitude toward nature, but there is stil a question as to whether the concern for non-human nature should be a part of professional engineering ethics rather than an engineer’s personal ethics.